Breathable film is an environmentally friendly breathable (vapor) water barrier (liquid, bacteria, dust) functional material. The emergence of microporous breathable film has a history of more than 20 years, the last 10 years has been rapid development.

Breathable film is a necessary material for adult diapers, the structure of adult diapers is divided into 3 layers: surface covering layer, absorbent core layer and bottom layer.

The surface layer of the adult diaper is made of non-woven fabric, the absorbent core layer is absorbent beads with fluffy fibers, while the bottom material is mainly made of PE film or PE film + non-woven fabric, the main purpose of the PE breathable bottom film is to prevent leakage.

Polyolefin breathable film, it is made by adding inert filler into PE or PP carrier, through film making and stretching. Used for personal hygiene care products, breathable film is an upgraded product of ordinary waterproof film. Breathable film and ordinary film can not be a simple replacement, the final product of the structure design is reasonable or not on the breathable membrane of the breathable effect of the embodiment of the vital!

Breathable Film Breathable Principle

The so-called breathable film, is through the polyolefin raw materials uniformly added to mix a functional inorganic products, so that the products in the film-forming process due to high-fold stretching and produce air holes, so as to have breathable, moisture-conducting function; breathable film function in short: waterproof, breathable (moisture), to the most commonly used PE as a carrier for the breathable film as an example.

Principle of Breathability

The principle is very simple: inorganic material + stretch = microporous, in fact, the operation is very delicate, only the right size, uniform distribution of microporous is effective as shown in Figure 1:

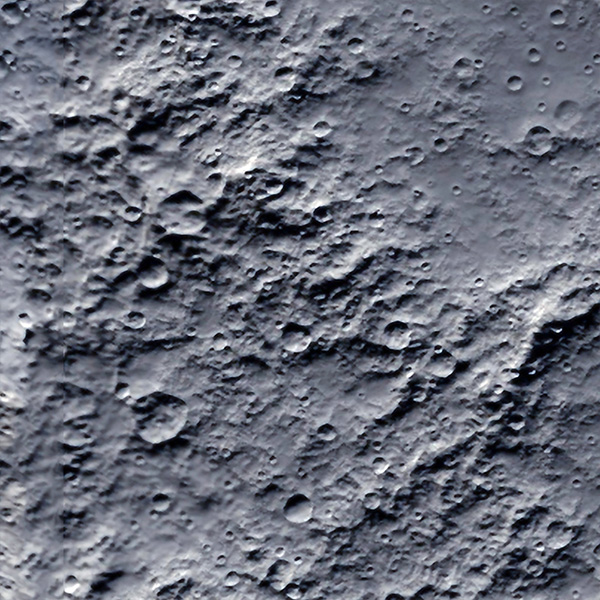

Effective pore size of breathable film

Effective pore size of breathable film

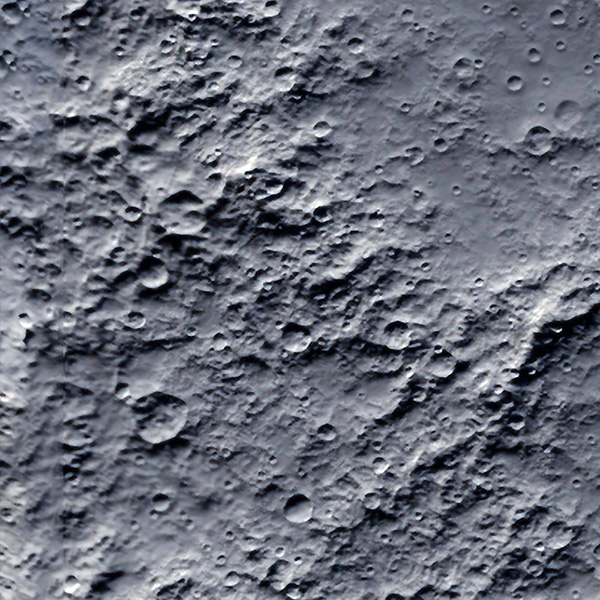

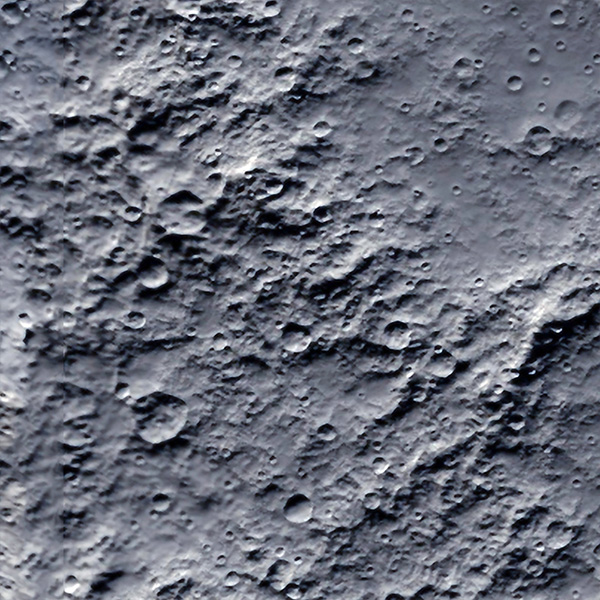

As shown in Fig. 2 and 3 below, insufficient stretching and pore size is too small, insufficient stretching and no pore size, poor stretching and undersized microporous can only be waste products.

correct stretching and cavitation

poor stretch conditions and insufficient cavitation

poor stretch conditions and no cavitation

Basic Film Formation Principle of Breathable Membrane

Breathable film forming principle: PE + CaCO3 (masterbatch) --- film forming --- stretching --- breathable film

PE breathable film is made by adding about 50% of special calcium carbonate to LDPE/LLDPE polyethylene resin carrier, and then stretching it for a certain period of time after extruding the film. As the polyethylene resin is a thermoplastic plastic material, can be stretched and crystallized under certain conditions, the interface between the polymer and the calcium carbonate particles peeled off when stretching, calcium carbonate particles around the formation of interconnected meandering pores or channels, it is these pores and channels to give the film's breathable (wet) function, thus communicating with the film on both sides of the environment.

Mechanism of action of breathable film

When the water vapor concentration on one side of the film is greater than the environment on the other side of the film, a humidity gradient pressure difference is formed. This provides the basic conditions for gas (vapor) convection, and the formation of convection results in a relatively balanced humidity environment on both sides of the film.

Breathable film used as a waterproof membrane, the liquid has a barrier effect, because the film exists in many pathways, it forms a zigzag channel “length-to-diameter ratio” (L/D) value is very large, can be understood as a capillary. Therefore, in the same liquid (such as water), the same pressure, as long as the height of the capillary column is less than the length of the capillary tube, you can ensure that the liquid will not leak out.

The water barrier properties of the film are therefore directly dependent on the pore size and path length of the permeable film. This performance is usually measured by the water pressure (ΔP), when the water pressure exceeds the value of the water pressure that the microporous membrane can withstand, the water will leak out.

According to the capillary principle above, the water pressure of the microporous membrane pores can be replaced by the capillary immersion pressure ΔP, which can be expressed by the following formula:

ΔP=2σcosα/d

Among them:

ΔP-soak pressure (Pa)

σ-Surface tension(N/m)

α-Contact angle(degree)

d-Capillary diameter

From this it can be seen that the WVTR (safety requirement) can be fulfilled by designing different microporous diameters and film thicknesses; obviously the WVTR can also be realized by varying the microporous diameter and microporous density of the film.

Note: For breathable films used in personal hygiene care products, the principle of improving the breathability of the film while ensuring safety (ΔP value) must be followed.

Technical Principles of Breathable Film Production

The manufacture of microporous breathable film can be divided into blown film and casting method according to the different film making process; it can be divided into unidirectional stretching method, bi-directional stretching method and local stretching method according to the different stretching process. Compared with ordinary PE cast embossed film, the manufacture of breathable film has higher technical requirements. In the production process, the following aspects should be paid special attention to:

Selection of raw materials

Resin Selection

Stiff breathable film - high density polyethylene; Flexible breathable film - low density polyethylene; High stretch breathable film - high strength polyethylene; Printing (color registration, position cutting) - high strength polyethylene

Selection of Calcium Carbonate

Surface treatment of calcium carbonate: fluidity, extrusion stability, die coking, pinholes, film mechanical properties, etc.

Selection of calcium carbonate particle size: tensile properties, moisture permeability, uniformity, processability.

The choice of raw materials directly affects the processability (such as coking time, extrusion stability, thin film production and pinhole defects, etc.) and physical properties (such as air permeability, water pressure, thermal stability and mechanical properties, etc.) of the breathable film. Therefore, the first thing to consider when selecting a permeable material is to make it suitable for the customer's physical requirements of the film and the matching condition with the processing equipment;

Dehumidification systems

The high humidity of raw material is the main reason for the holes in breathable film and the coking of T-film, which will seriously affect the production efficiency and product quality of breathable film. Therefore, the production of breathable film should not only dehumidify the raw material (<250ppm), but also should have strict humidity control requirements for raw material conveying and fringe recycling systems;

Extrusion thickness control

Stretching has an amplifying effect on the deviation of the extruded thickness, so the control of the extruded thickness is a prerequisite to ensure the uniformity of the thickness of the final product;

Tensile control

There are 2 necessary conditions for the manufacturing of breathable film, one is calcium carbonate and the other is stretching. Therefore, stretching is vital in the manufacturing process of breathable film. Stretching temperature, stretching ratio, stretching rate and stretching gap are the 4 elements of the stretching process, and its overall balance will have a great impact on the permeability, mechanical properties, consistency and appearance of the breathable film;

hot treatment (e.g. of metal)

Using heat treatment to restore and relax the stiff polymer chain segments after stretching is necessary to improve the stability of the breathable film material in the post-processing and use of the process.

Testing of breathable films

1、Water Vapor Transmit Rate WVTR:Water Vapor Transmit Rate

Recommended conditions:

Weight gain method---40℃.75%~90% humidity

Weight reduction method --- 40℃.50%~60% humidity

2、Air Passage Rate AP:Air Permeability ------sce/100cc

3、Shrinkage: %/80℃.15min

4、Water Pressure Resistance:mm

Principles of using breathable film

1, the final breathable effect of the embodiment of the inherent characteristics of the breathable film is the basis, but the structure of personal hygiene care products design is the key;

2、Used as a water barrier material, the safety of the breathable film (water barrier) is a prerequisite, and only under the premise of ensuring safety can we talk about breathability;

3, “wide - relatively wide”, “thin - thin, close to the body”, “package - relatively closed” type structure and relatively long time use (such as diapers, pads, etc.) of care products, the use of breathable film materials is necessary;

4, compared with ordinary PE embossed film, breathable film has its inherent shortcomings, so the design of the product should be good at avoiding shortcomings, to play to its strengths. For example, the transverse strength (CD) of the breathable film is low, the color is monotonous, poor thermal stability and so on;

5, the final breathable effect is directly proportional to the actual breathable area of the breathable film. Product design should cherish and protect the effective breathable area;

6, the final product design should consider the convection of small environment;

7, the effectiveness of breathable products in the user's body is time-lagged.

Applications for Breathable Membranes

Breathable film for adult diapers, sanitary napkins, medical mattresses, etc., in Europe and the United States and other countries has always had a stable demand, and the domestic sanitary materials market will be with the functionality, comfort needs and maturity, the demand for breathable film space will be more and more.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

ქართული